Specifiatications of configuration:

Mitsubishi PLC programmable controller stable performance and the overload current guarantee, system is safe and reliable and the XINJIE HD Touch Screen is used for control.

Upper and lower mould: 50#steel double-sided fine grinding the clamping precision reached ≤0.035MM never be deformed after quenching and tempering

The main oil circuit system uses the accessories provided by the Japan's first brand (YUKEN) to ensure high stability

Japan'sNHK slider:HRC-62 HIGH wear resistance with good verticality.

Added mechanism: auto lifting plate fuctions.

This equipment can be used together with the latest auto loading/unloading mechanism by this ,the operater is not required any longer.

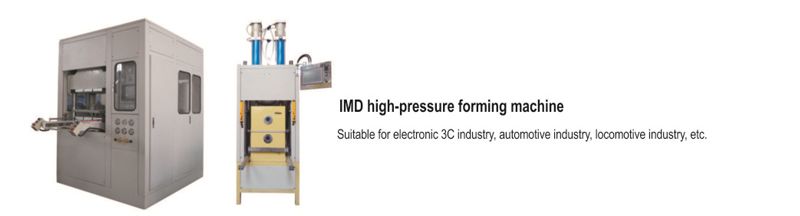

scope of product use:

1. Various types of flim plastic products

2.Suit for cutting of protected die of mobile phones or remote controls digital careras captops LCD SCREEN.

3.Various types of PET.PV.PC PMMA,ABS+PC and other thin film swithched washing machines film panel bulging drum packs molding ETC.

4.Molding of cars

5.Pressing of soft circuit of laptop key board.

6.Housing indoor building materials industry etc.

IMD (In-Mold Decoration, or Film Insert Molding) technology uses decorative (screen printing), 3-D molding and trimmed film materials as a thin shell, and then inserts plastic into the back of the thin shell through an injection molding process to make decorative components.

Through this special process, plastic parts with complex curves, 3-dimensional shapes with registered symbols, multi-color decorations, and light-transmitting designs can be easily produced. The IMD process can take over many post-molding operations, such as thermal transfer, screen printing, painting, laser etching, or electroplating of injection molded parts, thereby saving a lot of production costs.

It also provides unlimited decoration possibilities through precisely registered graphics on plastic parts. Back printing

Decorative applications make IMD products scratch-resistant and chemical-resistant to achieve long-lasting finishes.

Copyright © JAPLAU All Rights Reserved Technical Support:  https://new.cnzz.com/v1/login.php?siteid=1278629928 Sitemap

https://new.cnzz.com/v1/login.php?siteid=1278629928 Sitemap